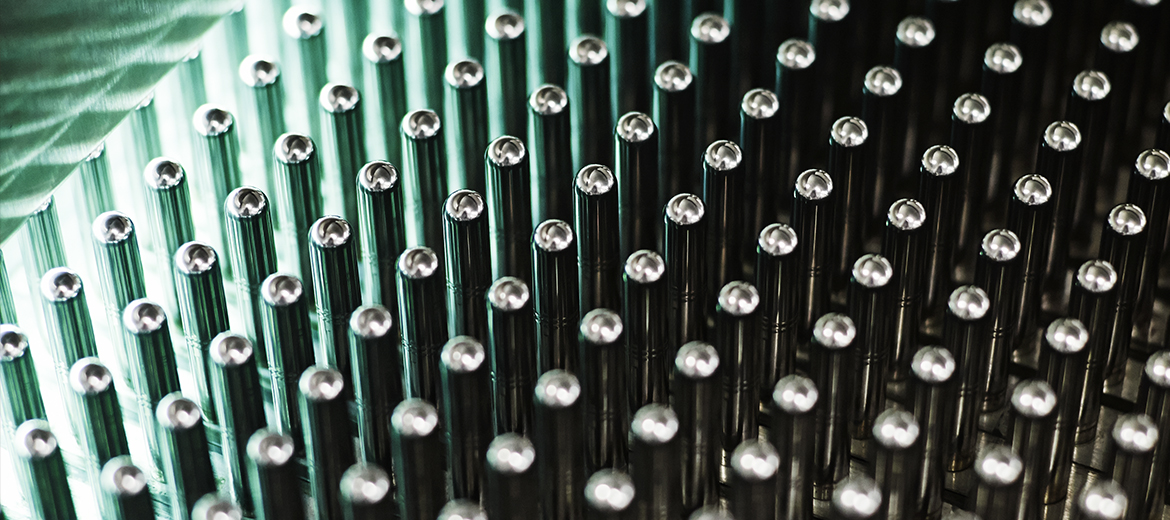

Process

Functionality and precision in mind and deed

Our capsules are manufactured under cGMP conditions and engineered to meet specific criteria related to strength, integrity and runnability on high-speed filling machines. Inprocess controls ensure compliance with target specifications, and high resolution inline optical inspection is employed to assure AQLs.In regard to Qualicaps® pharmaceutical processing equipment, all machines are available off the-shelf and specially designed to meet unique production or research needs. The process design incorporates the best technology to help our customers successfully and effortlessly fill and seal their products.